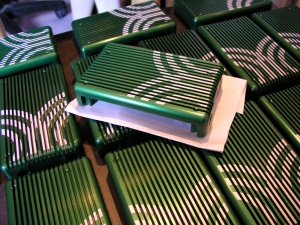

Outsourcing vs. In-House Manufacturing:

Why Companies should outsource Laser Cut & Engraved Products, Parts, & Service.

Small to Medium sized businesses often cannot afford high priced machinery. Larger businesses may NOT want to spend in-house time and internal costs for volume production. It is to the advantage of most businesses, therefore, to outsource parts fabrication to save material and machining costs. More than this, it is costly to hire employees needing to be trained to design using CAD, Computer Aided Design programs, then run high-tech machinery, such as CNC, computer numeric controlled equipment.

Other outsourcing advantages are:

- When businesses have uncertain projection for future volume production.

- Frequent design changes, and the resulting fixturing and machining changes which follow.

- Lack of in-house precision machining knowledge and expertise. Outsourcing helps companies gain access to higher technologies.

- Lack of storage space to store extra inventory of volume Products and Parts. Scheduling outsourced parts manufacturing as needed eliminates need for storing backstock.

- Knowledge of machining capabilities and limitations, needs to be considered when designing products. Therefore, rely on input and expertise of outsourced laser cutting and engraving specialists.

- Outsource specialists, such as CuttingEdgeLaser, are available to help co-design and develop parts and products.

- Outsourcing minimizes overhead costs by not needing to own equipment. Businesses then have a greater handle of cash flow and easier accounting.

- Outsourcing helps monitor parts and products inventories more easily.

- Outsourcing helps companies spend more time on those in-house manufacturing processes where it is most capable.

- Outsourcing assures businesses when increases in volume parts ordering and increased product demand are fulfilled on time.

- Rely on outsource manufacturing professionals to find, purchase, and use the very best and most appropriate materials for your projects.

- Outsourcing minimizes the purchasing department’s time researching material and parts sourcing.

You can always rely on outsourcing Cutting Edge Laser, with 18 years experience, to successfully produce precision part and products from your important designs. And we are always here, ready, and able to meet your growing volume demands during your company’s successful product sales and business growth.